Alfa Laval Unique Sampling Valve - Double Seat Valve

The Alfa Laval Unique Sampling Valve (Double Seat) is a double-seat sampling valve that enables representative sampling in hygienic processes under sterile conditions.

Alfa Laval Unique Sampling Valve - Double Seat Valve

The Alfa Laval Unique Sampling Valve (Double Seat) is a double-seat sampling valve that enables representative sampling in hygienic processes under sterile conditions. It provides the high accuracy, exceptional repeatability and excellent reliability required for high-quality, cost-effective sampling. Either the ergonomically designed handle or the actuator ensures exceptional control during the sampling operation. It is possible to sterilize the entire seat between sampling, thereby eliminating the risk of cross-contamination.

Applications

This double-seat sampling valve is specially designed for use in hygienic applications across the dairy, food, beverage, brewery, pharmaceutical, personal care and many other industries.

Benefits

- Safe, hygienic and contamination-free sampling

- Highly reliable operation

- Easy to operate and maintain

- Double seat with enhanced cleanability

- Modular design and easy to upgrade

- Sterilization possible

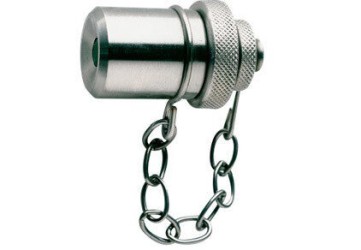

Standard design

The Alfa Laval Unique Sampling Valve (Double Seat) consists of a valve body made of a single piece of stainless steel, either an actuator for automatic operation or a handle for manual operation, and a rubber membrane seal placed on the stem of the actuator, which acts as a stretchable plug. The valve is available in three sizes: Type 4, Type 10 and Type 25. A collared pipe, tank or Tri-Clamp connection is available. The valve handles and actuators are interchangeable

Working principle

The Alfa Laval Unique Sampling Valve (Double Seat), with its patented technology, is designed for truly sterile sampling and ensures higher cleanability and sterilization of the valve seat and pipe connections. The double-seat sampling valve has three positions: open, shut and sterilization. It can be operated manually or automatically using a pneumatic actuator.

Open position: To start the sampling process 2900-0076 Manual valve: rotate the handle in a counterclockwise direction to open the valve. Pneumatic valve: open the valve by activating the actuator. This retracts the valve stem and membrane seal, which enables the product to flow freely through the open valve.

Shut position: To stop the sampling process 2900-0077 Manual valve: rotate the handle in a clockwise direction to close the valve. Pneumatic valve: shut the air supply to stop the flow of product from the valve. In closed position, the valve body is now ready for sterilization. If steam is used for Sterilization-inPlace, the use of an optional pressure relief valve on the outlet is recommended to ensure proper steam temperature in the valve.